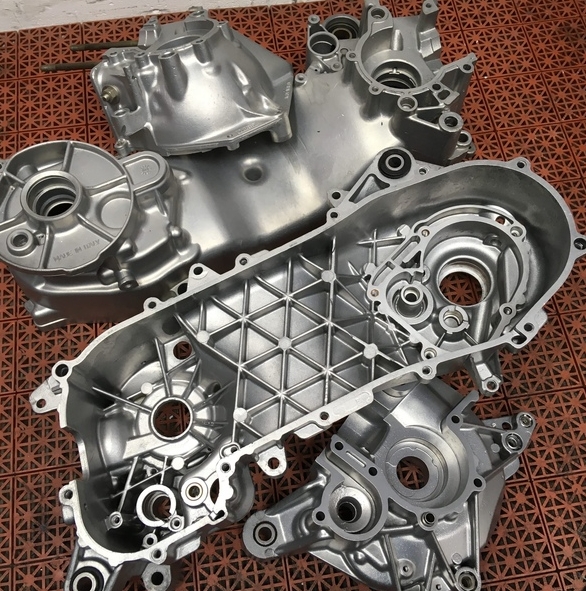

Aquablasting – a modern method of gentle surface cleaning

The traditional method of sandblasting industrial surfaces, which is harmful to human health, is being replaced by aqua-blasting – gentle cleaning. It is a modern method of soft cleaning from rust, scale, carbon deposits, paint and other hard-to-clean contaminants from various surfaces: steel, aluminum, glass, plastic. The process consists of applying a pressurized, directional jet of suspension consisting of water and abrasive particles to the surface to be cleaned.

The technology of aquablasting allows fast, soft and ecological cleaning of parts without harming soft materials and harmful emissions into the environment, protects the surface from rusting and oxidation, does not change the geometric dimensions, and reduces roughness. Slurry circulation makes the cleaning process cost-effective and low-cost.

The application of the technology has a number of advantages:

dust-free blasting

high cleaning quality

gentle cleaning so that the surface remains undamaged

harmless for people and the environment

Multiple use of the abrasive, a considerable saving of financial and operating costs and time

The scope of aquablasting is diverse, it is surface cleaning in the automotive industry, repair and maintenance, restoration work, removal of paint, rust, carbon deposits, descaling after hardening for engineering products, removal of small burrs and tool traces after turning and milling, satinization and passivation of stainless steels (including after welding works), treatment of special materials and alloys, as well as surface preparation before gluing, painting, chemical and galvanic coatings.

PARTSWASHERS team developed and tested the aquablast unit. The unit is a chamber with a closed cleaning cycle. Washing components – a fine fraction of glass beads (glass beads) sized 200-300 microns and ordinary tap water.

Machine body is made of stainless steel including a tank for storage and mixing of washing components. The lid with glass and holes for hands with protective gloves, allows you to make the cleaning process as convenient as possible. The machine is equipped with a natural ventilation system and lighting inside the chamber.

The cleaning process is as easy as possible. The parts are placed on the turntable. The operator closes the lid of the machine and starts the mixing process (lifting the settled) on the bottom of the glass beads by turning on the pump. The aqua-blasting gun is equipped with a cleaning solution supply fitting with glass beads and an air supply fitting. The operator presses the foot pedal to deliver the water/glass bead mixture through the gun to the surface of the part to be cleaned. A turntable allows the operator to easily rotate the part to be cleaned. Once the cleaning process is complete, the part is ready for further processing operations.

The main criterion for selecting this equipment is the maximum dimensions and weight of the part to be cleaned.